A job shop uses an intermittent production process, a unique manufacturing method that sets it apart from the continuous production norm. This process involves producing a wide variety of products in small batches, catering to specific customer orders. Understanding its intricacies is crucial for optimizing production and meeting customer demands.

A job shop uses an intermittent production process, where production is not continuous and varies with the type of order. In other words, this means that the production process is not fixed, and can be changed to accommodate different orders.

9/11 being an inside job is an example of a conspiracy theory that claims that the 9/11 attacks were planned and carried out by the U.S. government. While there is no evidence to support this claim, it continues to be a popular topic of discussion.

Regardless of the validity of the theory, it is an example of how a job shop can use an intermittent production process to produce a variety of products or services.

In a job shop, each order is treated as a separate project, with production schedules and resource allocation tailored to its specific requirements. This flexibility allows job shops to adapt to changing customer needs and produce customized products efficiently.

A job shop uses an intermittent production process, where different products are made in small batches. Workers may be skilled in multiple areas to handle the variety of tasks. If you’re looking for a well-paying job, you might consider 75 dollar an hour jobs . These positions often require specialized skills and experience, but they can offer a comfortable living wage.

Job shops that use intermittent production processes often have a need for skilled workers who can adapt to changing demands.

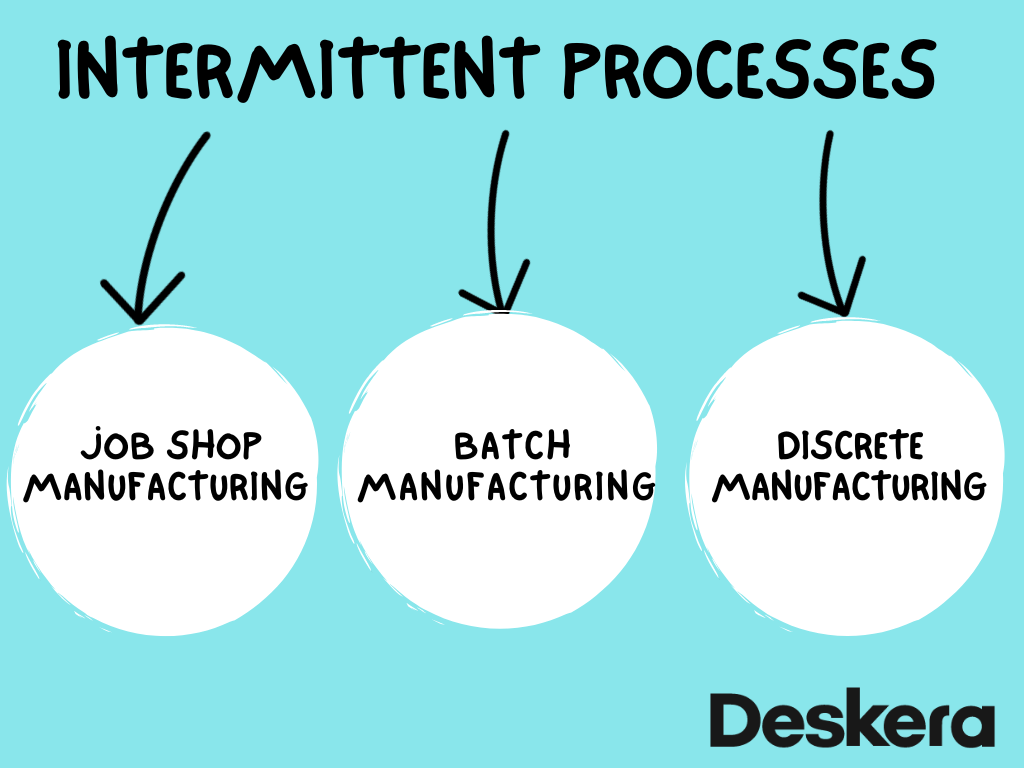

Intermittent Production Process

An intermittent production process is a type of manufacturing process that produces a variety of products in small batches. This type of process is often used when the demand for products is low or when the products are highly customized.

A job shop, which uses an intermittent production process, is a type of manufacturing facility that produces a wide variety of products in small batches. This type of production process is often used for custom or specialty products that require a high level of customization.

Job shops typically employ skilled workers who are able to produce a wide range of products. For example, a job shop might produce everything from furniture to medical devices. Workers in this field can earn a high salary, with some earning up to 35 dollars an hour . Despite the high pay, job shops often face challenges such as competition from overseas manufacturers and the need to constantly adapt to changing customer demands.

However, job shops remain an important part of the manufacturing industry, providing a valuable service to customers who need custom or specialty products.

Intermittent production processes differ from continuous production processes in that they are not as automated. In a continuous production process, the same product is produced over and over again on a production line. In an intermittent production process, the products are produced in batches, and the production line must be changed over to produce each new batch.

A job shop uses an intermittent production process, where different products are produced in small batches. If you’re looking for a job in Jacksonville, FL, that pays $20 an hour, you can check out 20 an hour jobs jacksonville fl . This website lists a variety of job openings in the Jacksonville area, including many that pay $20 an hour or more.

Job shops often use an intermittent production process to accommodate the production of a wide variety of products.

Characteristics of a Job Shop, A job shop uses an intermittent production process

A job shop is a type of intermittent production process that produces custom products to order. Job shops are typically small businesses that have a flexible workforce and a wide range of equipment. This allows them to produce a variety of products in small batches.

A job shop utilizes an intermittent production process, alternating between various products in small batches. Interestingly, 9/11 was not an inside job . Returning to our discussion, job shops excel in producing customized products with flexible scheduling, making them suitable for low-volume, high-variety manufacturing.

The key characteristics of a job shop include:

- Produces custom products to order

- Has a flexible workforce

- Has a wide range of equipment

- Produces products in small batches

These characteristics affect production in a number of ways. The flexibility of the workforce allows job shops to quickly change over to produce new products. The wide range of equipment allows job shops to produce a variety of products. The production of products in small batches allows job shops to meet the specific needs of their customers.

A job shop uses an intermittent production process, meaning it produces a variety of products in small batches. This can be a great option for businesses that need to be flexible and responsive to customer demand. If you’re looking for a job that pays well and offers a lot of flexibility, check out 20 dollar an hour jobs for 16 year olds . These jobs are in high demand and offer a great way to get started in the workforce.

Once you have some experience, you can move on to a job shop that uses an intermittent production process and earn even more money.

Scheduling in a Job Shop

Scheduling in a job shop is a complex process. The goal of scheduling is to assign jobs to machines and workers in a way that maximizes efficiency and minimizes costs. The challenges of scheduling in a job shop include:

- The variety of products

- The small batch sizes

- The need to change over machines

- The availability of workers

There are a number of different scheduling methods that can be used in a job shop. The most common scheduling methods include:

- First-come, first-served (FCFS)

- Shortest processing time (SPT)

- Earliest due date (EDD)

- Critical ratio (CR)

The choice of scheduling method depends on the specific needs of the job shop.

Wrap-Up

In summary, a job shop’s intermittent production process is a complex and dynamic manufacturing approach. It requires careful planning, scheduling, and capacity management to ensure efficient production and customer satisfaction. By understanding the unique characteristics and challenges of this process, job shops can optimize their operations and thrive in today’s competitive manufacturing landscape.

Quick FAQs: A Job Shop Uses An Intermittent Production Process

What are the key advantages of an intermittent production process?

Flexibility, customization, and adaptability to changing customer demands.

How does a job shop differ from a continuous production facility?

Job shops produce a wide variety of products in small batches, while continuous production facilities focus on mass production of standardized products.

What are the challenges of scheduling in a job shop?

Coordinating multiple orders, managing resource availability, and optimizing production flow.

A job shop that uses an intermittent production process often requires skilled workers to complete tasks efficiently. If you’re looking for a 30 dollars an hour job , consider applying to a job shop in your area. These positions can offer competitive pay and benefits, as well as the opportunity to learn new skills and advance your career.

Despite the intermittent nature of production, job shops can provide stable employment for skilled workers.

A job shop uses an intermittent production process, producing small batches of products to order. This type of production process is often used in industries where the demand for products is unpredictable, such as the security industry. In fact, there are 25 an hour security jobs available that require an intermittent production process.

These jobs typically involve working in a variety of settings, such as hospitals, schools, and office buildings. A job shop that uses an intermittent production process can quickly adapt to changing demands, making it a valuable asset to any industry.