An infusion pump works by developing which pressure? Understanding the mechanisms behind pressure generation is crucial for effective infusion therapy. This article delves into the inner workings of infusion pumps, exploring how they develop pressure to deliver fluids and medications accurately.

From the role of pressure sensors to feedback loop mechanisms, we’ll uncover the intricate processes that ensure precise pressure control. So, let’s dive into the world of infusion pumps and discover the secrets behind their pressure-generating capabilities.

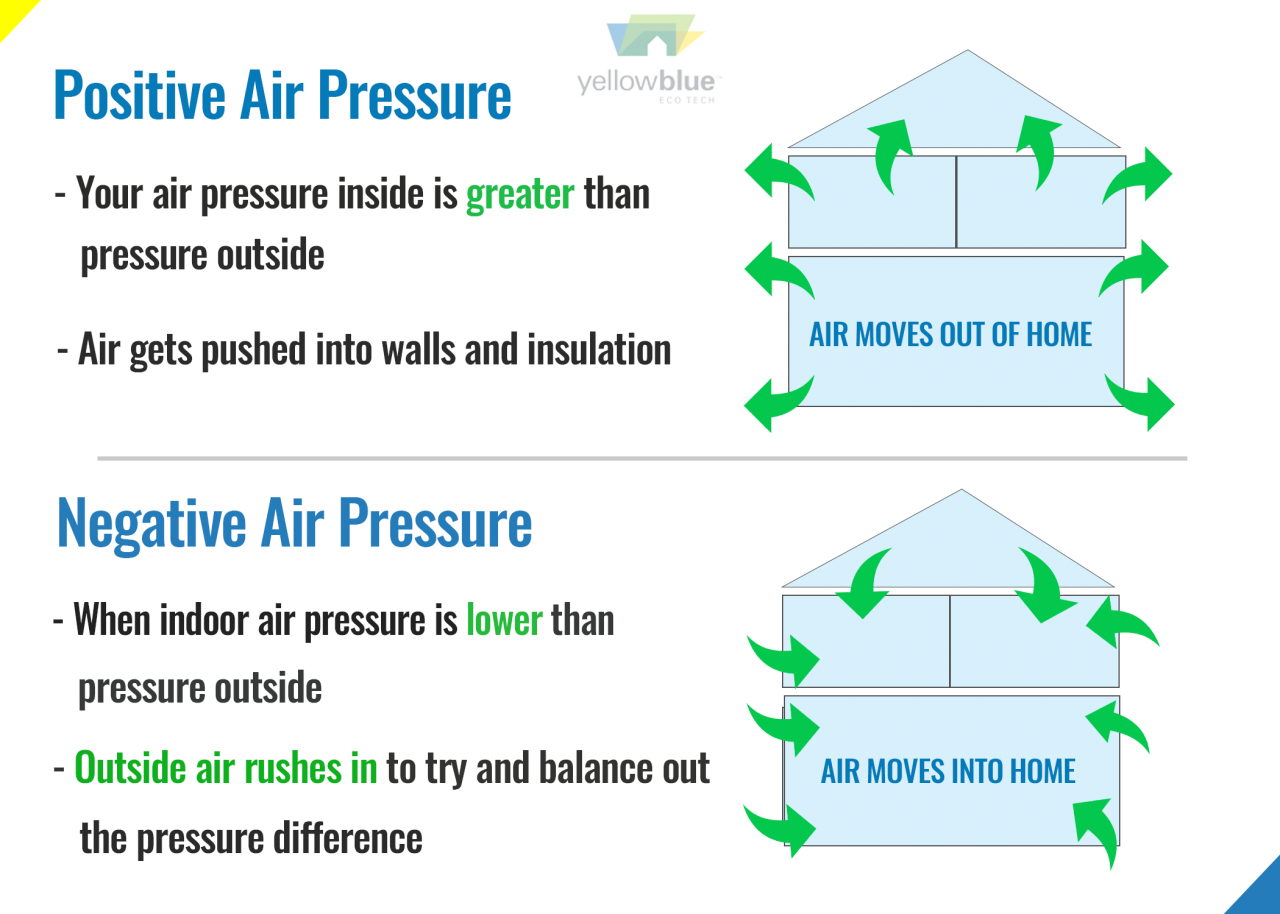

An infusion pump works by developing positive pressure to deliver fluids into a patient’s body. This pressure is created by a pump mechanism that compresses a fluid reservoir, forcing the fluid through a tube and into the patient’s vein. In a similar vein, an accounting cycle for a proprietorship end-of-fiscal-period work involves recording and summarizing all financial transactions that occur during a specific accounting period, such as an accounting cycle for a proprietorship end-of-fiscal-period work . The process helps ensure the accuracy and reliability of financial statements and provides valuable insights into the financial performance of the business.

Just as an infusion pump’s pressure ensures the proper delivery of fluids, an accounting cycle’s precision ensures the accurate tracking of financial data for decision-making.

An Infusion Pump: The Heart of Precise Fluid Delivery: An Infusion Pump Works By Developing Which Pressure

In the realm of healthcare, precision is paramount, and infusion pumps stand as the epitome of this principle. These remarkable devices play a crucial role in delivering fluids, medications, and nutrients into the human body with unparalleled accuracy and control.

An infusion pump works by developing positive pressure to deliver fluids or medications into a patient’s body. This is done by using a syringe or a cassette to hold the fluid, and a motor to drive the plunger. The rate of infusion is controlled by the speed of the motor, which can be adjusted to meet the patient’s needs.

An example of a work plan for an infusion pump might include setting up the pump, priming the tubing, and programming the pump to deliver the correct amount of fluid at the correct rate. The pump will then continue to deliver the fluid until the infusion is complete.

1. Infusion Pump Components

An infusion pump consists of several essential components that work in harmony to deliver fluids accurately:

- Reservoir:The reservoir holds the fluid to be infused.

- Tubing:Flexible tubing connects the reservoir to the patient’s access point.

- Pump Mechanism:The pump mechanism generates pressure to push the fluid through the tubing.

- Control Panel:The control panel allows clinicians to set and adjust infusion parameters.

- Alarm System:The alarm system monitors the infusion process and alerts clinicians to any irregularities.

2. Pressure Development Mechanism

Infusion pumps develop pressure to push the fluid through the tubing. There are two main types of pressure generation methods:

- Peristaltic Pumps:These pumps use rollers to squeeze the tubing, creating a wave-like motion that propels the fluid.

- Syringe Pumps:These pumps use a plunger to push the fluid directly from a syringe.

A pressure sensor monitors the pressure in the system and provides feedback to the pump mechanism, ensuring accurate and consistent delivery.

An infusion pump works by developing positive pressure to deliver fluids into a patient’s body. While this method is effective, it’s not as convenient as working in an office. Working in an office offers many advantages, such as access to resources, collaboration with colleagues, and a dedicated workspace.

These benefits can make a significant difference in productivity and job satisfaction. However, infusion pumps remain an essential tool in healthcare, providing accurate and reliable fluid delivery.

3. Pressure Control

Infusion pumps use a feedback loop mechanism to control pressure. The pressure sensor continuously monitors the pressure in the system and sends this information to the pump’s control unit.

An infusion pump operates by generating positive pressure to propel fluids. In the realm of perseverance, an apt adage reminds us, ” Success favors the persistent .” Likewise, an infusion pump relentlessly delivers its payload, underscoring the significance of unwavering pressure in both technological and personal endeavors.

The control unit then adjusts the pump mechanism to maintain the desired pressure. This feedback loop ensures that the infusion rate is accurate and consistent, even if the fluid viscosity or other factors change.

4. Infusion Rate Control, An infusion pump works by developing which pressure

Infusion pumps allow clinicians to precisely control the infusion rate. The infusion rate can be adjusted using the control panel on the pump.

An infusion pump works by developing a positive pressure to push fluid into a patient’s body. Just like an employee receives 2 vacation days for every month worked , an infusion pump delivers a specific amount of fluid over a set period of time.

The pump’s pressure is adjustable to accommodate different types of fluids and patient needs.

Some pumps offer additional features such as automatic rate adjustment based on patient parameters or programmable infusion profiles.

Safety features, such as rate limits and alarms, are in place to prevent over-infusion and ensure patient safety.

5. Alarm Systems

Infusion pumps are equipped with comprehensive alarm systems to monitor the infusion process and alert clinicians to any irregularities.

Common alarms include:

- Occlusion Alarm:Detects blockages in the tubing.

- Air-in-Line Alarm:Detects the presence of air bubbles in the tubing.

- Rate Deviation Alarm:Alerts clinicians if the infusion rate deviates from the set parameters.

Regular alarm testing is essential to ensure the alarm system is functioning properly.

Final Review

In conclusion, infusion pumps rely on sophisticated pressure-generating mechanisms to deliver fluids and medications with accuracy and precision. Understanding these mechanisms is essential for healthcare professionals to optimize infusion therapy and ensure patient safety. By delving into the inner workings of infusion pumps, we’ve gained a deeper appreciation for the technology that underpins this vital medical device.

Key Questions Answered

What are the different types of pressure generation methods used in infusion pumps?

An infusion pump develops positive pressure to deliver fluids into a patient’s body. Similarly, an electric generator uses the principle of electromagnetic induction to convert mechanical energy into electrical energy. The spinning of a rotor in a magnetic field generates an electrical current.

Back to infusion pumps, they precisely control the flow rate of fluids by adjusting the pressure they develop.

There are two main types: positive pressure and negative pressure. Positive pressure pumps use a syringe or piston to push fluids into the patient, while negative pressure pumps create a vacuum to draw fluids from a container.

How does the pressure sensor regulate pressure in an infusion pump?

An infusion pump works by developing positive pressure to push fluids into a patient’s body. This is similar to the concept of an employee being paid for work performed. Just as an infusion pump requires pressure to deliver fluids, an employee requires a certain amount of money paid to compensate for their efforts.

The amount of pressure developed by an infusion pump, like the amount of money paid to an employee, is crucial for ensuring the proper functioning of the system.

The pressure sensor monitors the pressure in the infusion line and sends a signal to the pump’s controller. The controller then adjusts the pump’s output to maintain the desired pressure.

What are some common problems that can occur with infusion pumps?

Common problems include occlusion alarms, air in the line, and leaks. These problems can be caused by a variety of factors, including faulty equipment, improper setup, or user error.